2025-03-11

CMZ introduces X - ray nondestructive testing solutions to customers in Chongqing casting and die casting plants

Shenzhen Comm Intelligent Equipment Co., Ltd. is a high-tech company integrating research and development, production and sales of X-ray nondestructive testing equipment and robot visual appearance testing equipment. The company focuses on IC packaging, casting, lithium battery, SMT, LED, and other industries to provide testing solutions. Our team is composed of Japanese and Korean technicians who have been engaged in intelligent detection industry for many years. Our company strictly in accordance with the ISO9001 quality system requirements, comprehensive management and control of product quality. We continue to pursue innovation in product processes and applications to meet customer requirements

2025-12-15

Essential Considerations for Wholesale Power Lithium Battery X-ray Testing

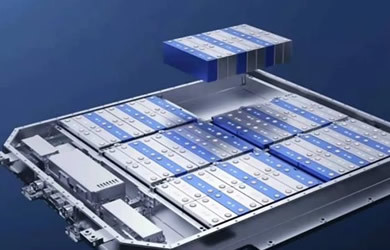

In the fast-evolving landscape of electrical engineering, particularly in the domain of battery technology, the significance of thorough testing cannot be overstated. Among the various testing methods, X-ray testing for wholesale power lithium batteries has emerged as a vital tool for ensuring safety and reliability. This process involves the use of X-ray imaging to inspect the internal structures

2025-12-10

Unlocking Quality: The Critical Role of X-ray Inspection for Wholesale Cylindrical Batteries

Unlocking Quality: The Critical Role of X-ray Inspection for Wholesale Cylindrical Batteries

Table of Contents

1. Introduction to Cylindrical Batteries and Their Applications

2. The Importance of Quality Assurance in Battery Manufacturing

3. Understanding X-ray Inspection Technology

4. Benefits of X-ray Inspection for Cylindrical Batteries

5. Implementing X-ray Inspection in P

2025-12-05

Understanding OEM Die Casting X-Ray Inspection: A Key to Quality Assurance

In the manufacturing industry, especially within sectors that rely on precision components, the quality assurance of products is paramount. One of the essential techniques employed in this process is OEM die casting X-ray inspection. This method serves as a non-destructive testing (NDT) tool that evaluates the internal structure of die-cast components, ensuring they meet the necessary quality stan

2025-11-30

A Comprehensive Exploration of OEM Semiconductor Device X-ray Testing Procedures

A Comprehensive Exploration of OEM Semiconductor Device X-ray Testing Procedures

Table of Contents

1. Introduction to OEM Semiconductor Device X-ray Testing

2. Importance of X-ray Testing in Semiconductor Manufacturing

3. Principles of X-ray Testing Technology

4. The Process of X-ray Testing for OEM Semiconductor Devices

4.1 Preparation and Setup

4

2025-11-25

Understanding Customized Wire Harness X-Ray Inspection: Elevating Quality Assurance in Non-Destructive Testing

In industries where reliability and safety are non-negotiable, the significance of customized wire harness X-ray inspection cannot be overstated. This innovative method utilizes X-ray technology to examine wire harness assemblies, which are crucial in transmitting electrical signals and power in complex systems. The inspection process is designed to detect potential issues such as improper connect

2025-11-20

Why Customized Capacitive Wire Harness Inspection is Essential for Quality Control

Why Customized Capacitive Wire Harness Inspection is Essential for Quality Control

Introduction to Capacitive Wire Harness Inspection

In the world of manufacturing and assembly, the **quality control** of wire harnesses is paramount. Customized capacitive wire harness inspection has emerged as a vital tool in ensuring that electrical connections are reliable and safe. This process not only guarant

2025-11-15

Essential Considerations for Buying X-ray Testing Systems in Non-Destructive Testing

In the field of non-destructive testing (NDT), X-ray testing systems play an invaluable role in evaluating materials and components without causing any damage. When considering a purchase, it is essential to focus on several technical aspects to ensure you select the right system for your specific applications.

First, consider the type of X-ray technology you require. There are various types of X-

2025-11-10

Transforming Inspections: The Benefits of New X-ray Technology in Electrical Applications

Transforming Inspections: The Benefits of New X-ray Technology in Electrical Applications

Table of Contents

1. Introduction

2. Understanding X-ray Technology

3. Applications of X-ray Technology in Electrical Inspections

4. Key Benefits of Using X-ray Technology for Inspections

5. Improving Safety and Compliance in Electrical Inspections

6. Future Trends in X-ray Inspection

2025-11-07

Ensuring Quality: The Critical Role of Wire Harness X-ray Inspection in Modern Manufacturing

Ensuring Quality: The Critical Role of Wire Harness X-ray Inspection in Modern Manufacturing

Table of Contents

1. Introduction to Wire Harness X-ray Inspection

2. The Importance of Quality Control in Manufacturing

3. What is Wire Harness X-ray Inspection?

4. Benefits of Wire Harness X-ray Inspection

4.1 Enhanced Quality Assurance

4.2 Cost Efficiency and Waste Reduction

2025-11-07

Unlocking Precision: The Importance of Customized Semiconductor Device X-ray Testing

In the realm of semiconductor manufacturing, the demand for high-performance and reliable devices is continuously escalating. As these components become more complex and miniaturized, traditional testing methods often fall short. This is where customized semiconductor device X-ray testing proves essential. This non-destructive technique allows for a detailed examination of the internal architectur

2025-11-05

Power of Durable X-ray Inspection Solutions for Non-Destructive Testing

Durable X-ray inspection solutions play a pivotal role in non-destructive testing by providing reliable, detailed, and timely insights into material integrity